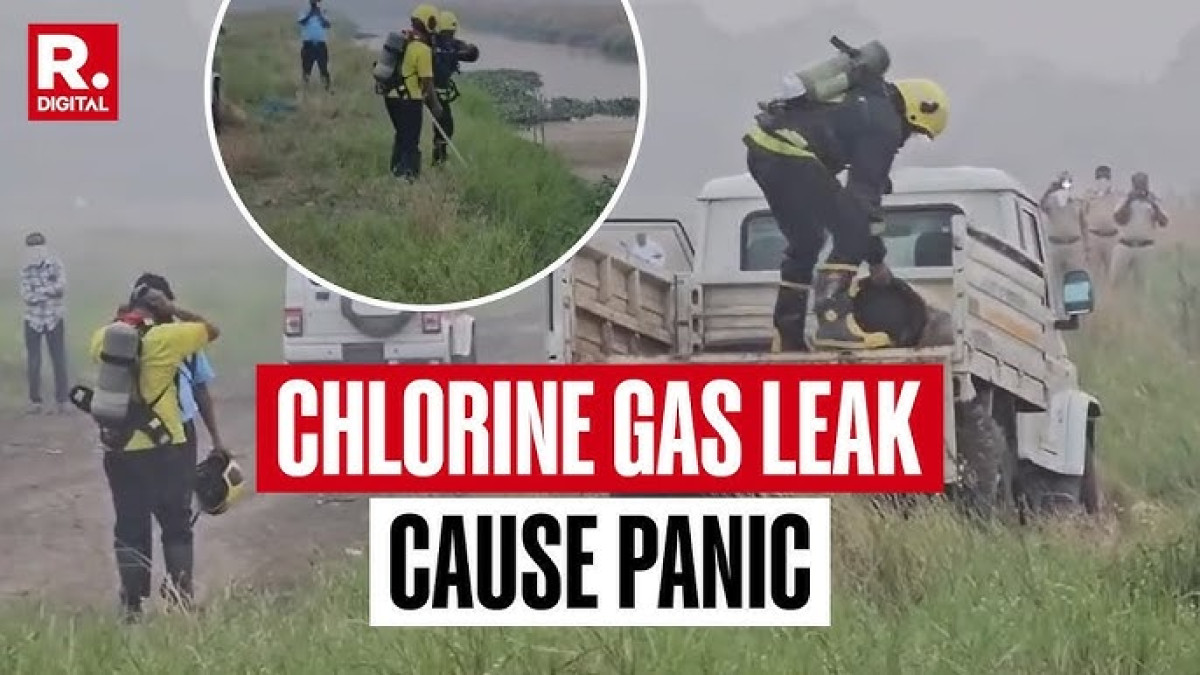

A recent chlorine gas leak in the Jaora Industrial Area of Ratlam, Madhya Pradesh, has once again highlighted the critical need for proper emergency gas-handling systems in chemical facilities. The incident occurred when chlorine escaped from a 40-kg tank at a Ferric Sulphate manufacturing unit, leading to chaos across the industrial zone and sending two factory workers and three fire officials to the hospital. Although all victims are now out of danger, the three hour struggle to stop the leak exposed severe gaps in safety preparedness. Workers initially tried to manually plug the leak and failed, forcing fire brigades and external chemical response teams to intervene. The leaking unit had reportedly been non-operational for days, and the staff was unable to control the situation. As a result, nearly ten nearby factories had to halt their operations as a precaution, and the unit’s management now faces legal action for negligence. This incident demonstrates how quickly a toxic release can escalate when a facility lacks engineered emergency systems. Had an APZEM Emergency Scrubber been installed, the entire event would have unfolded very differently. Emergency scrubbers are designed to activate instantly when a hazardous gas leak occurs or when a safety valve lifts. Instead of workers attempting dangerous manual intervention, the chlorine would have been automatically captured, absorbed, and neutralized within the scrubber before spreading into the environment. This would have prevented worker exposure, protected the fire brigade personnel, avoided hospitalizations, stopped chemical dispersion, and eliminated the need to shut down surrounding factories. Emergency scrubbers operate even when the plant is idle, providing continuous protection and ensuring immediate containment of sudden high-volume leaks. In Ratlam, such a system could have prevented panic, property impact, operational disruption, environmental contamination, and legal consequences. The lesson is clear: emergencies do not wait, and relying on manual response is both unsafe and outdated. With hazardous gases like chlorine, ammonia, HF, SO₂, and other corrosive or toxic vapors, a dedicated emergency scrubbing system is not optional, it is essential. APZEM Emergency Scrubbers offer rapid, reliable, automatic containment that protects people, the plant, and the surrounding community. Incidents may be unpredictable, but their impact does not have to be. The right emergency scrubber can turn a potential disaster into a controlled event, safeguarding lives, compliance, and uninterrupted industrial operations.