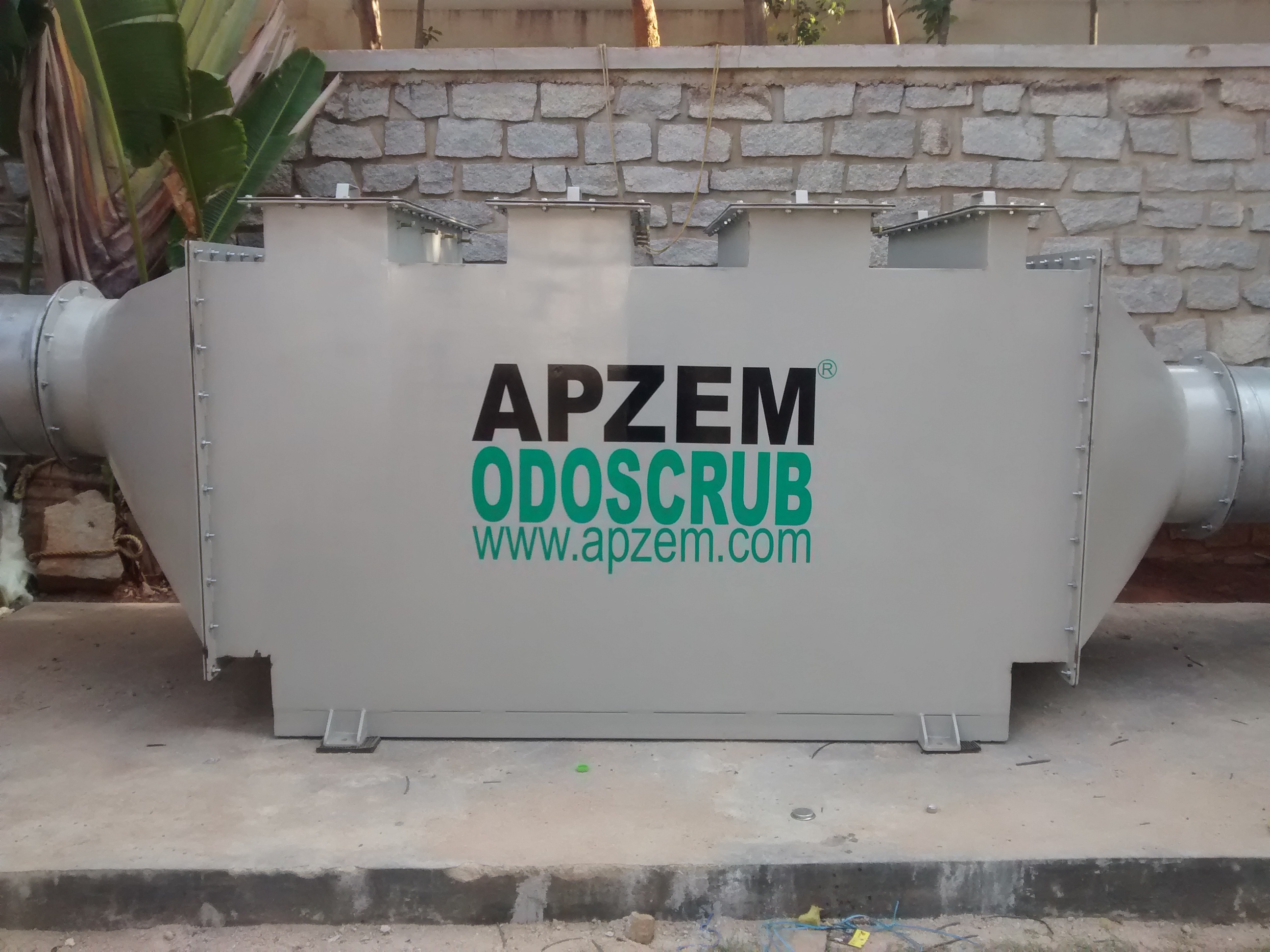

APZEM adsorption scrubber is a highly effective air pollution control device designed to remove toxic gaseous contaminants from industrial exhaust streams through the process of adsorption. In this process, pollutants are captured on the surface of a solid adsorbent material, such as activated carbon, silica gel, or zeolites. The gas stream containing harmful substances passes through a packed bed or a series of trays filled with the adsorbent, where the pollutants adhere to the surface of the adsorbent particles.

This method is particularly efficient for removing volatile organic compounds (VOCs), odors, and certain hazardous air pollutants that are not easily captured by other scrubbing techniques. The adsorbent material are custom tailored to target specific contaminants, ensuring optimal removal efficiency.

Adsorption scrubbers are known for their simplicity and reliability, with relatively low maintenance requirements compared to other types of scrubbers. Once the adsorbent material becomes saturated with pollutants, it can be regenerated or replaced, ensuring continuous operation.

Covers 1 year warranty from the date of installation