APZEM waste incineration scrubber is a critical air pollution control device designed to effectively remove harmful pollutants generated during the incineration of waste materials. This scrubber ensures that emissions released into the atmosphere are significantly cleaner, protecting public health and the environment. Waste incineration processes produce a variety of contaminants, including particulate matter, acidic gases, heavy metals, and dioxins, which must be carefully managed to comply with stringent environmental regulations.

The scrubber operates by channeling the incinerator exhaust gases through a series of treatment stages. Initially, the hot gases pass through a quench chamber to rapidly cool them, reducing the formation of dioxins and furans. The gases then enter the main scrubbing unit, where they come into contact with a scrubbing liquid, typically a water-based solution with alkaline agents like sodium hydroxide (NaOH) or lime. This liquid absorbs and neutralizes acidic gases such as sulfur dioxide (SO2) and hydrochloric acid (HCl), converting them into less harmful compounds.

Additional stages may include particulate filters or electrostatic precipitators to capture fine particulates and heavy metals, as well as activated carbon filters to adsorb dioxins and other organic pollutants. The cleaned gas is then released into the atmosphere, significantly reducing the environmental impact of the incineration process.

Waste incineration scrubbers are essential for waste management facilities, ensuring they operate within environmental standards and protect air quality. By efficiently removing a wide range of pollutants, these scrubbers contribute to safer, cleaner incineration practices and support sustainable waste management solutions.

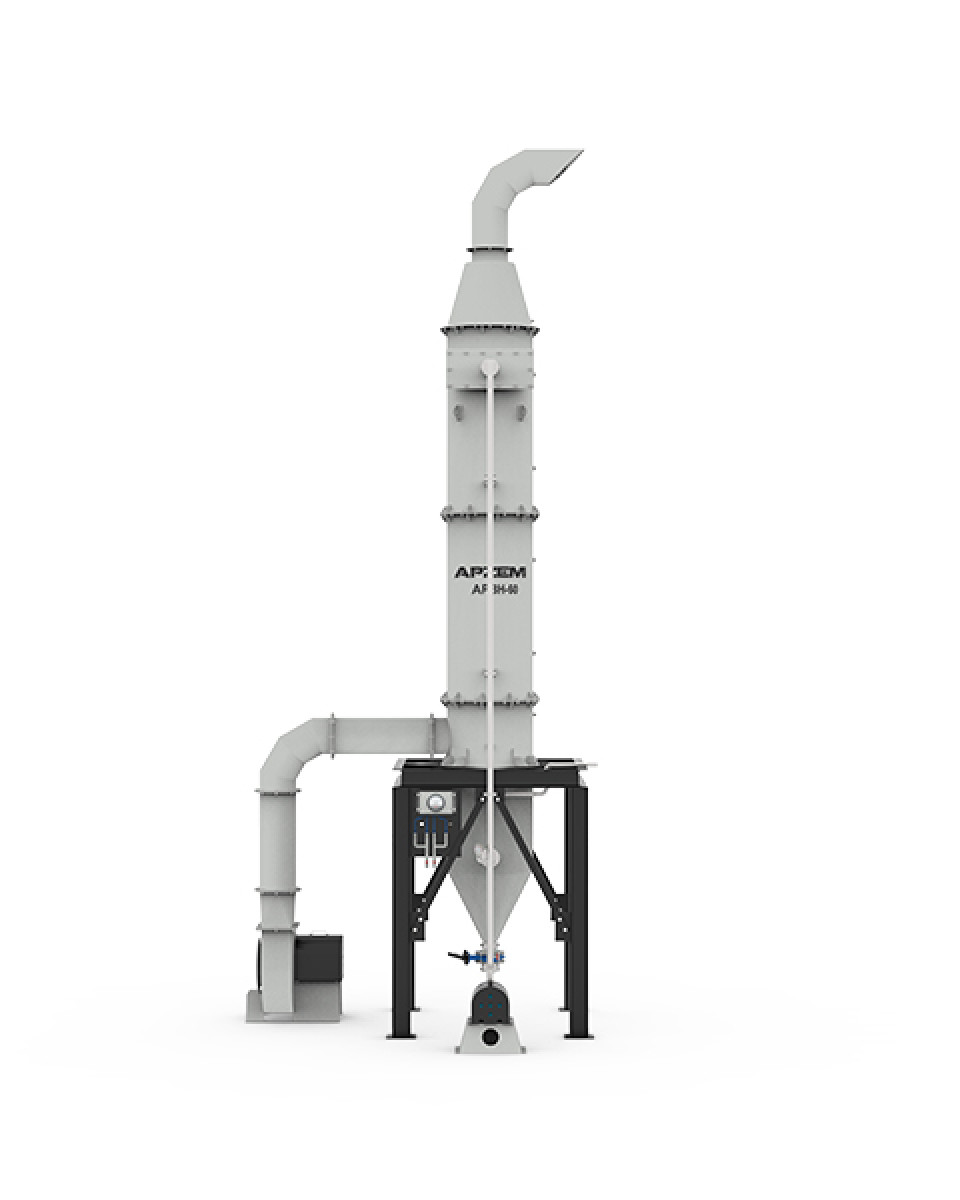

waste-incineration-scrubber

View / Download1. Drain valve with butterfly valve

2. Float valve

3. Inspection glass port

4. Magnehelic gauge

5. Protection valve for magnehelic gauge

6. Nozzles

Covers 1 year warranty from the date of installation