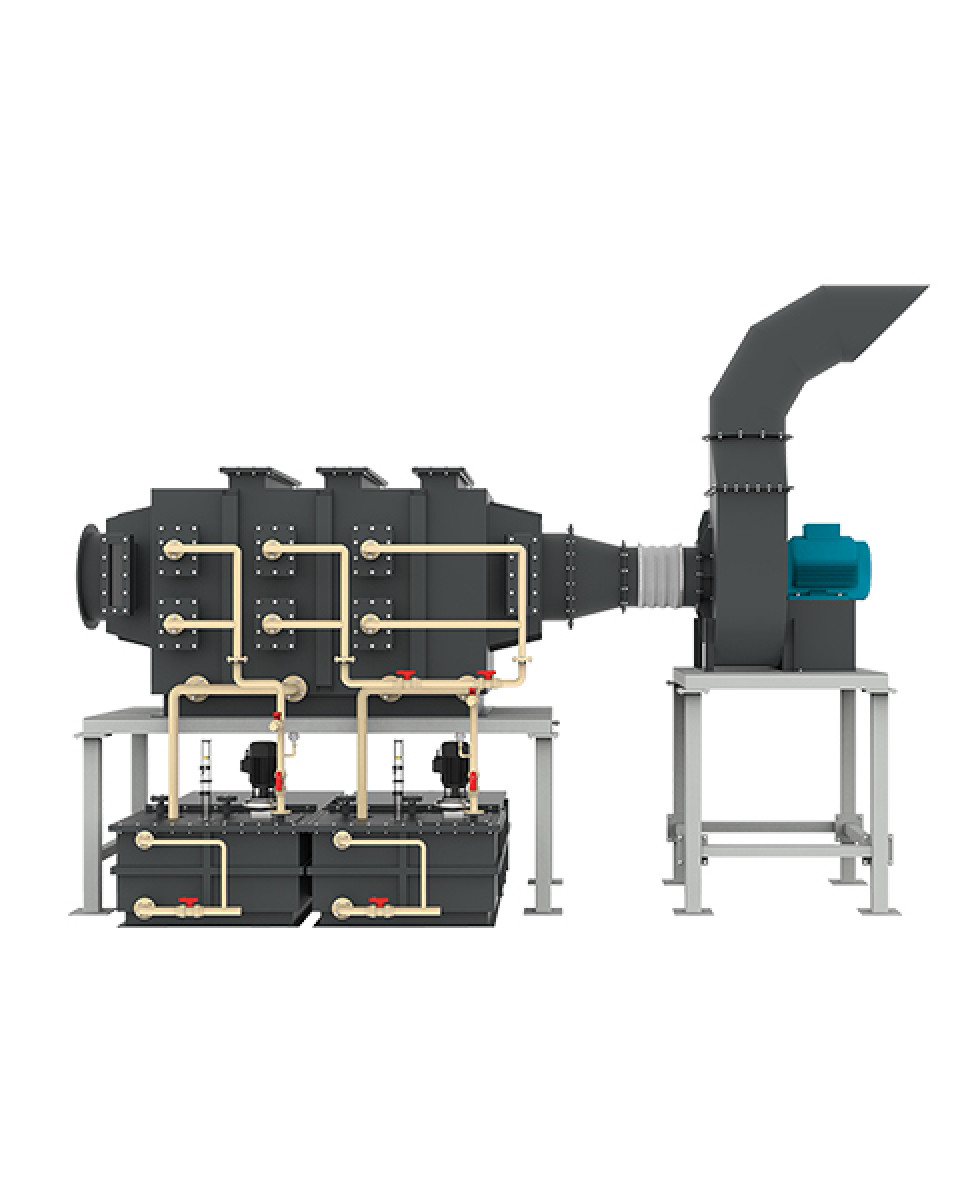

APZEM chromic acid scrubber is a specialized air pollution control device designed to safely remove chromic acid mist and other hazardous chromium compounds from industrial exhaust streams. Chromic acid, used in various processes such as electroplating, anodizing, and chemical manufacturing, poses significant health risks and environmental hazards if released untreated.

Chromic acid scrubbers are essential for industries such as electroplating, metal finishing, and aerospace manufacturing, where chromium compounds are widely used. These scrubbers not only protect worker health by preventing inhalation of toxic fumes but also ensure compliance with stringent environmental regulations. By effectively removing harmful chromium emissions, chromic acid scrubbers contribute to safer industrial operations and significant environmental protection. Their robust design and efficient operation make them a vital component in facilities dealing with chromic acid and similar hazardous substances.

Max air handling volume- Upto 20,000 CFM

Removal efficiency- Above 99.9 %

MOC: PVC + FRP

Designed with composite mesh pads

Spray nozzles for optimal dispersion with wide coverage and distribution

High energy efficient motors with improved lifespan

Covers 1 year warranty from the date of installation