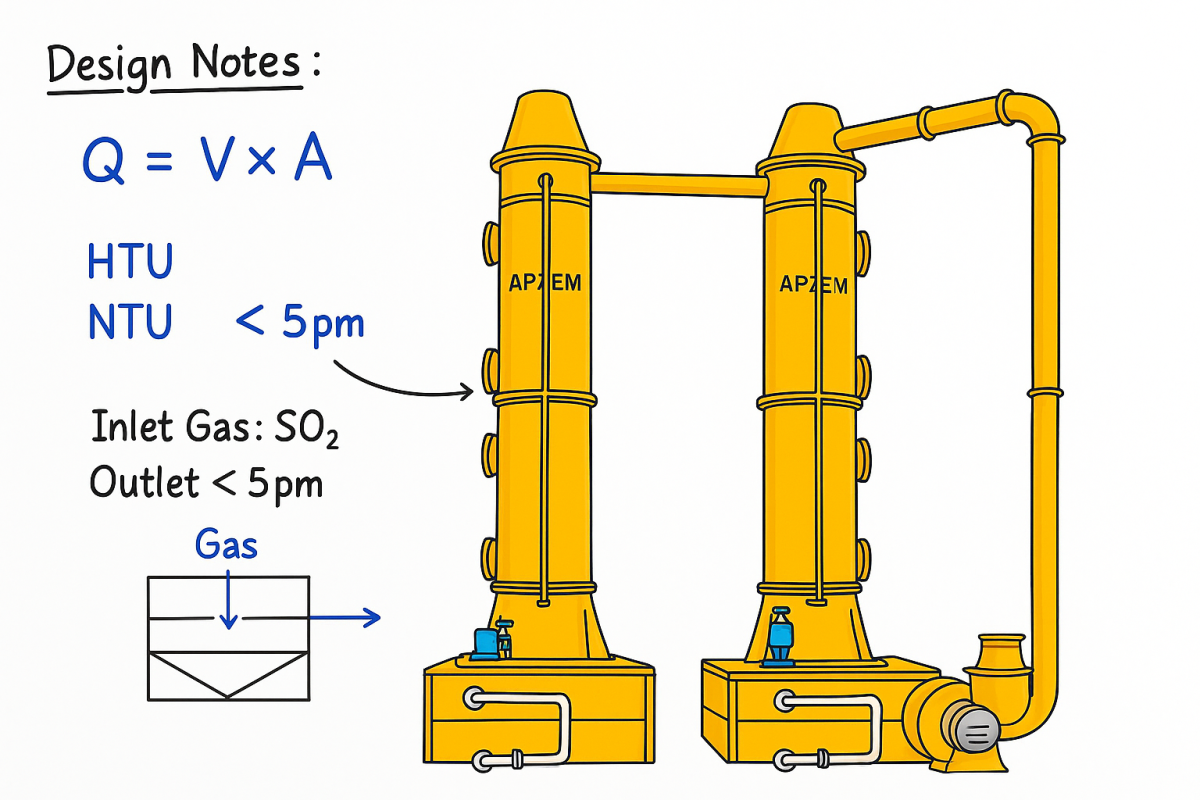

At Apzem, scrubber design is a scientific process and not an exercise in guesswork. Each system is engineered with gas chemistry, mass-transfer principles, and application-specific safety standards for accurate and reliable performance. Recently, we have designed multi-stage scrubbers for various dangerous gases, such as Ethylene Oxide, Phosphine, POCl₃, PCl₃, HF, HCl, HBr, SO₂, NO₂, Methyl Bromide, and ammonia from refrigeration vents. For each project, we study the behavior of the gas, select the correct scrubbing media, select the right material of construction, and design a system to meet stringent emission norms. Decisions are based upon actual customer data and gas load—never assumptions.

A key part of our work is to determine the scrubber's height, diameter, and packing. These dimensions are scientifically calculated using gas flow characteristics, required removal efficiency, packing surface area, contact time, HTU/NTU concepts, liquid recirculation rates, and pressure-drop limits. In this way, every Apzem scrubber will be precisely sized: not oversized, not underperforming, but exactly engineered for the application.